- Volume: 500 to 60,000 litres

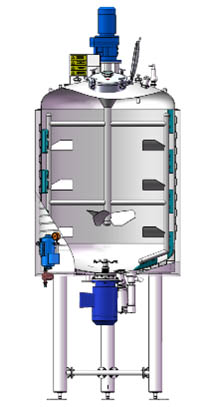

- Pressure: -1 to +6 barg

- Version: atmospheric, clean, ultra-clean, sterile

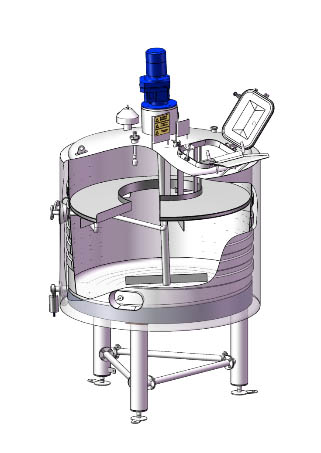

Pendulum agitator, anchor type agitator with PTFE scrapers, and/or bottom of the tank.

Heatexchange viaa coil onthe bottom and on the shell.

Watertight weldedinsulation.

Cleaning with spray balls on the tank roof and washing valves on the side.

Vacuum aspiration of the powders, at the bottom of the tank

Integration of the powders, using a saw tooth propeller or a rotor stator at the bottom of the tank.

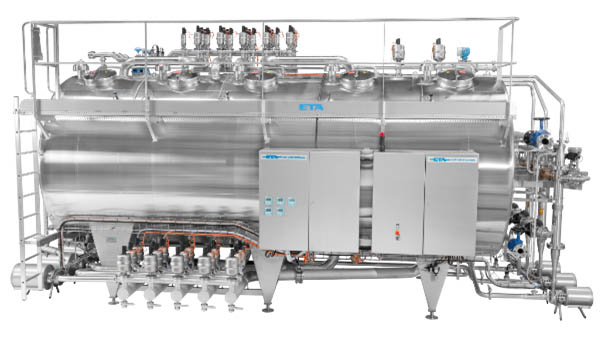

Applications: manufacture of creams, mascaras, shampoos, lotions, lipsticks, etc.

Our standards are given as a reference, however, our extensive experience and skills enable us to adapt them to your needs.

Technical documents available for download

- PEMCA –500 to 8,000 litres – Process tank, under atmospheric pressure

- PEMCP –500 to 8,000 litres –Process tank, under pressure

- PEMTA–10,000 to 60,000 litres – Process tank, under atmospheric pressure

- PEMTP – 0.1 bar –10,000 to 60,000 litres – Process tank, under pressure