Mixercookers:

Objectives: preparing, blending, cooking, concentrating, homogenous mixture, efficient heatexchange, slow agitator, with PTFEscrapers, built-in cleaningguaranteed.

Applications:dairy desserts, mixed vegetables, soups, fruit preparations, jams, fruitpurees, sauces, etc.

Our standards are given as a reference, however, our extensive experience and skills enable us to adapt them to your needs.

Technical documents available for download

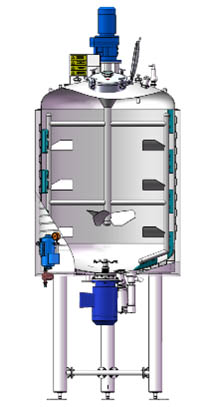

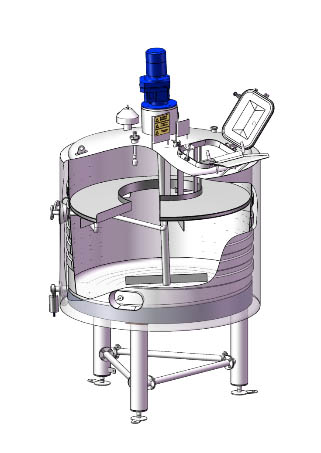

PEMCA – 500 à 8 000 litres – Tank process, à pression atmosphérique

PEMCP – 500 à 8 000 litres – Tank process, sous pression

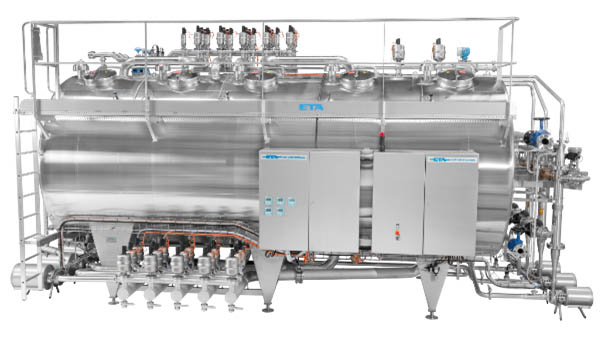

PEMTA- 10 000 à 60 000 litres – Tank process, à pression atmosphérique

PEMTP – 0,1 bar – 10 000 à 60 000 litres – Tank process, sous pression